What makes a Titleist a Titleist? What separates a Titleist from all other golf balls? There are many important differences, but one can be seen right on the surface of the ball. If you hold a Pro V1 in one hand and a Pro V1x in the other, you'll quickly notice that the dimples on V and X are not the same. The same is true for any two Titleist golf ball models that you compare.

Unlike other golf ball manufacturers who apply the same dimple pattern to multiple products they put out in the market, Titleist creates unique dimple patterns as an integral part of our design process – for every golf model we offer. By doing so, we're able to tailor very specific performance characteristics to fit the needs of very different types of golfers. Mike Madson, Titleist Senior Director of Golf Ball Research & Engineering explained:

“Each Titleist golf ball model flies differently, because each golf ball has its own unique optimized aerodynamic design. Golf ball aerodynamics are largely a function of dimples—the number, the depth, the edge angle, and shape can all affect ball flight."

To achieve different flight profiles, Titleist scientists and engineers are in constant pursuit of new dimple configurations. Titleist R&D has designed, prototyped, and tested thousands of different dimple configurations. Only a small fraction of those designs ultimately make it to production. In fact, in 2021, when new dimple patterns were created for Pro V1 and Pro V1x, R&D tested over 60 different versions of the 388 tetrahedral dimple design before finding just the right configuration for Pro V1. And R&D needed to experiment with 35 different versions of the 348 tetrahedral dimple design before identifying the pattern that would check all the boxes for Pro V1x.

But finding the right pattern is only the beginning. R&D implements a subsequent, rigorous process to squeeze every last drop of performance out of the golf ball's aerodynamics.

"After finding the best dimple pattern," Mike explained, "we optimize the depth of the dimples. As we make dimples shallower, the golf ball's going to fly higher in the air. As we make dimples deeper, the golf ball is going to fly lower. Somewhere in between those two extremes is an optimal trajectory that is going to maximize the possible distance for that dimple pattern and the golfer."

Making these incremental changes requires months of testing – in the laboratory, in our indoor test range (ITR), and at our Manchester Lane Test Facility where prototype iterations are tested using our proprietary robot hitters.

Just how small are the modifications that we make from one test ball to the next?

"When we make the tooling to do this," Mike said, "we're only changing the dimple depths by about 2/10,000 of an inch for each iteration. To put that into context, that's about the size of a red blood cell. Our ability to precisely control the depth of the dimples, and detect these differences, allows us to optimize trajectory and achieve industry-leading distance."

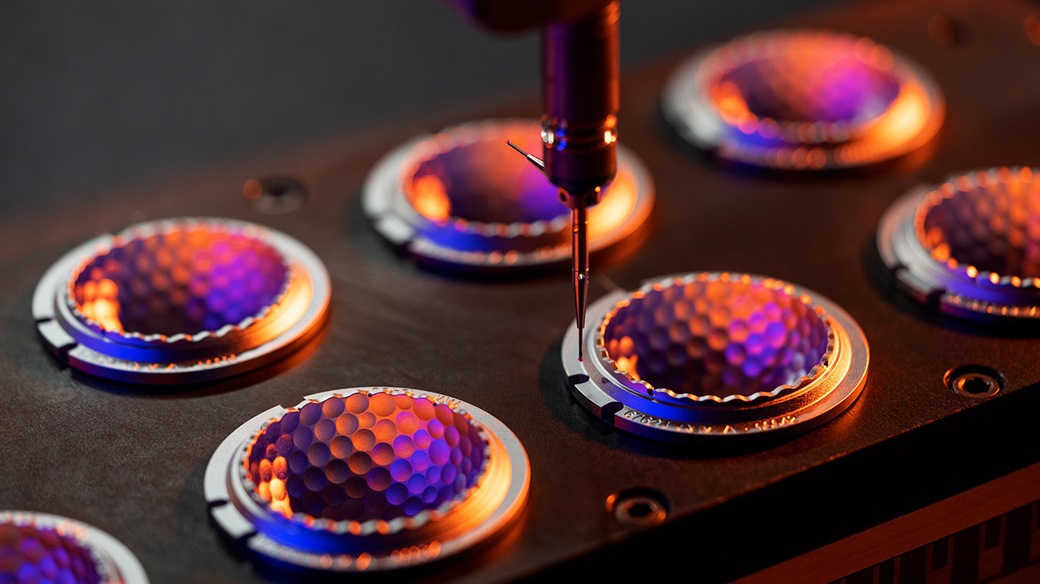

The degree of precision required to exact these minuscule changes is only possible because of Titleist's dedicated Machine and Tooling operations. In addition to making much of the proprietary machinery used in our golf ball plants, it's here that dimple designs from R&D come to life in the form of mold cavities. Mold cavities are the steel dies that are used during manufacturing to impress dimple patterns into the cover of the golf ball.

Between aerodynamic design development, prototype testing, dimple optimization and final golf ball production, tens of thousands of mold cavities are needed each year. It's a difficult and expensive process, and you might wonder, 'Why doesn't Titleist just outsource some of this precision machining?' As Mike Madson explained, it comes down to you, the golfer:

"There is a direct correlation between the way a golf ball is made and the way it performs on the golf course. We insist on making our own cavities because it's the only way to ensure that every single mold cavity produces the same result. Our research has shown that a golf ball with uneven dimple depths, off by as little as the width of a human hair, can turn a good swing into a bad shot, and cause your ball to fly offline. That's why we insist on owning every step in our manufacturing process. So that every Titleist golf ball you tee up performs like a Titleist."

● ● ●

Want to learn more about how Titleist golf balls are designed and manufactured? Take a Digital Tour of Titleist Ball Plant 3.

If you'd like to know which Titleist golf ball model is right for you game, visit our Golf Ball Fitting & Education Resources, where you can schedule a live, one-on-one virtual golf ball consultation with a member of the Titleist Golf Ball Fitting team and access the Titleist Golf Ball Selector Tool.

#TeamTitleist